The maturing U.S. population combined with expanding health awareness is fuelling the drug blister packaging market. Further, proof-based medicine and patient-driven medicines are driving the requirement for special medication solutions and packaging.

Plastic packaging has the best space for development and growth due to buyers requesting more refined packaging and a more prominent feeling that all is well with the world including child-safe packaging.

Future Market Insights projects the pharmaceutical packaging market growing at a CAGR of almost 6% through 2029.

The plastics segment has the best potential, with about $36 billion of steady freedom.

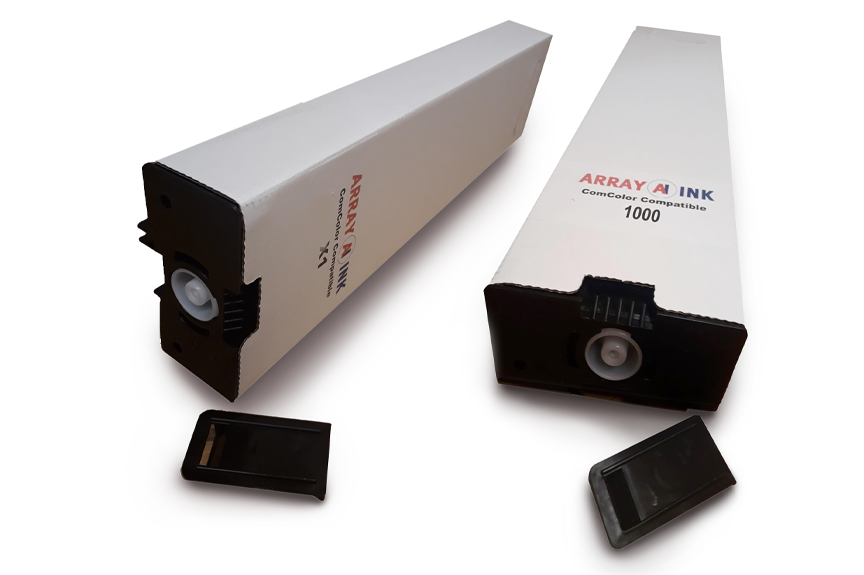

As the business incorporates packaging past iconic plastic bottles, conveying printed data is moving to adaptable digital inkjet printing. More limited creation runs and the requirement for printing re-did data or security coding makes inkjet printing ideal.

When to use inkjet printing for blister packaging

Many people falsely assess the topic of utilizing digital vs. ordinary printing as an either-or suggestion. The appropriate response can regularly be that either situation might be opportune independently or a blend of the two. Digital printing offers the chance of personalization, coding, and the expansion of safety highlights.

Moreover, digital printing of drug packaging bodes well for use without a moment to spare creation, which decreases the requirement for keeping an enormous stock of items with a restricted timeframe of realistic usability.

Business destinations drive the decision of printing innovation. For the most part, if printing less than 500,000 pieces, duplicate changes frequently, or the process duration is short, then, at that point, it merits assessing digital printing as an answer.

Advantages of digital printing for blister packaging:

- - Reduce inventory costs

- - Speed to market

- - Lower unit printing costs

- - Serialization or personalization

- - Colour consistency

Digital inkjet is best for blister packaging when:

- - Consumer demands require holding lower-volume SKUs in inventory.

- - You need to reduce prepress, warehousing, or waste from expiring products.

- - You are increasingly concerned with brand and product security.

Inkjet ink considerations for blister packaging

Shopper wellbeing and the printing substrate drive the selection of inks. Drug packaging might utilize foil, solid paper, or a polyethylene fibre material like Tyvek.

A large portion of the digital printing technology for packing printing is piezo inkjet technology (PIJ). The substrate decides the ink required. Indeed, even inconspicuous contrasts in substrates can affect the accomplishment of the ink utilized. It is ideal to test ink definitions on examples of the substrate for the ideal outcomes. Kao Collins, for instance, can test inks on the expected substrates utilized for fixing blister packaging.